Exploring the Versatility of Garnet Blasting Media in Various Industries

Release time:

2025-07-19

Exploring the Versatility of Garnet Blasting Media in Various Industries Table of Contents Introduction to Garnet Blasting Media What is Garnet Blasting Media? Key Properties of Garnet Blasting Media Applications of Garnet Blasting Media in Various Industries Garnet in the Construction Industry Garnet in the Automotive Industry Garnet i

Exploring the Versatility of Garnet Blasting Media in Various Industries

Table of Contents

- Introduction to Garnet Blasting Media

- What is Garnet Blasting Media?

- Key Properties of Garnet Blasting Media

- Applications of Garnet Blasting Media in Various Industries

- Garnet in the Construction Industry

- Garnet in the Automotive Industry

- Garnet in the Aerospace Industry

- Garnet in the Marine Industry

- Garnet in Metal Finishing

- Benefits of Using Garnet Blasting Media

- Environmental Impacts of Garnet Blasting Media

- Choosing the Right Garnet Blasting Media for Your Needs

- Frequently Asked Questions

- Conclusion

Introduction to Garnet Blasting Media

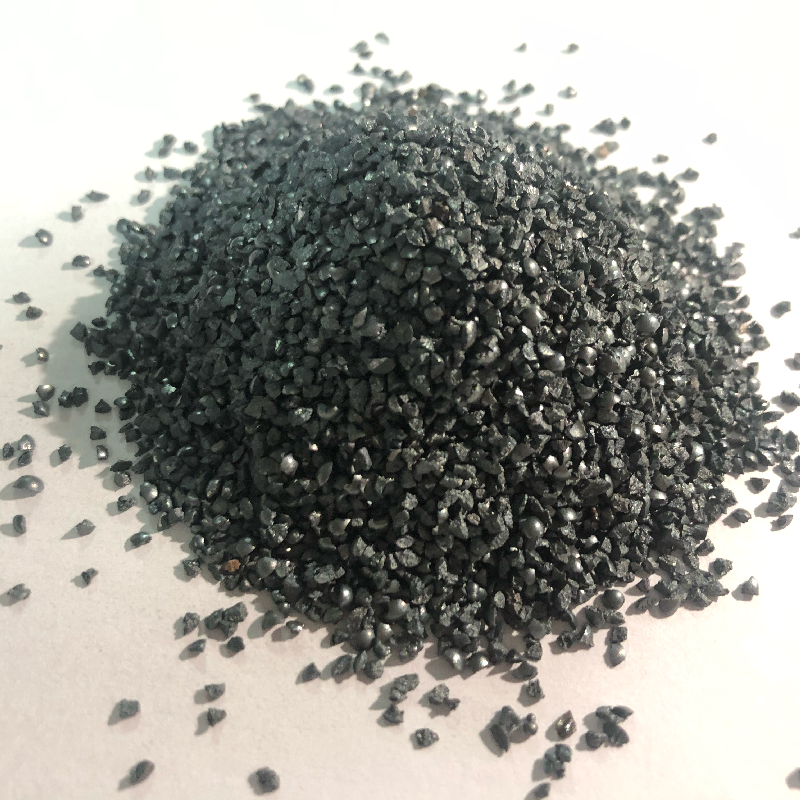

In the realm of industrial abrasives, **garnet blasting media** stands out as an exemplary choice, revered for its efficiency and versatility. Known for its natural hardness and angular shape, garnet is derived from a group of silicate minerals, primarily found in metamorphic rocks. With its unique properties, garnet is increasingly becoming the go-to abrasive for a variety of applications, ranging from surface preparation to waterjet cutting, across multiple industries.

What is Garnet Blasting Media?

Garnet blasting media is a type of abrasive material used in sandblasting and other surface preparation processes. It is made from crushed garnet stones that are processed into various grades to suit different applications. The hardness and angularity of garnet particles make them ideal for effectively removing contaminants, rust, and old coatings from surfaces without causing significant damage to the underlying material.

Key Properties of Garnet Blasting Media

Garnet blasting media exhibits several key properties that contribute to its effectiveness.

1. Hardness

With a Mohs hardness rating of 7.5 to 8.0, garnet is significantly harder than many other abrasive materials, allowing it to cut through tough surfaces efficiently.

2. Angular Shape

The angular shape of garnet particles enhances their cutting ability, making them more effective for surface preparation compared to rounded abrasives.

3. Low Dust Generation

One of the significant advantages of garnet is its low dust generation during use, which leads to a cleaner working environment and better visibility for operators.

4. Eco-Friendly

Garnet is a natural mineral and is less harmful to the environment compared to synthetic abrasives, making it a more sustainable choice for many industries.

Applications of Garnet Blasting Media in Various Industries

Garnet blasting media finds utilization across a myriad of industries, each leveraging its unique properties for diverse applications.

Garnet in the Construction Industry

In the construction sector, garnet is widely used for surface preparation on various materials. It effectively removes contaminants like rust, old paint, and dirt from surfaces before painting or coating, ensuring better adhesion and a longer-lasting finish.

Garnet in the Automotive Industry

Automotive manufacturers and repair shops utilize garnet blasting media for cleaning and preparing metal parts. Its effectiveness in stripping away old coatings and contaminants makes it a staple in both restoration and manufacturing processes.

Garnet in the Aerospace Industry

The aerospace sector demands high precision and quality, making garnet an ideal choice for surface preparation on aircraft components. Its ability to provide a clean surface without damaging the underlying material is crucial for ensuring safety and performance.

Garnet in the Marine Industry

Garnet blasting media is used extensively in the marine industry for hull cleaning and maintenance. Its effectiveness in removing barnacles, algae, and other marine growth helps in maintaining vessel performance and longevity.

Garnet in Metal Finishing

In metal finishing processes, garnet serves as an essential abrasive for polishing and smoothing surfaces. It helps achieve a refined finish that is critical for aesthetic and functional purposes.

Benefits of Using Garnet Blasting Media

The benefits of garnet blasting media extend beyond its applications. Here are some compelling reasons to choose garnet for your abrasive needs:

1. Cost-Effective

While garnet may have a higher initial cost compared to some other abrasives, its durability and efficiency often lead to lower overall costs due to reduced consumption and less frequent replacement.

2. Superior Performance

Garnet's hardness and angular shape provide superior cutting power, allowing for faster completion of projects and improved surface finishes.

3. Versatility

With its wide range of applications, garnet can be used for various tasks across different industries, making it a versatile choice for businesses.

4. Eco-Friendly Option

As a natural mineral, garnet is a more environmentally friendly abrasive when compared to synthetic alternatives, promoting sustainable practices in industrial operations.

Environmental Impacts of Garnet Blasting Media

Garnet blasting media is considered a more environmentally friendly option due to its natural composition. It does not contain harmful chemicals, making it safer for both operators and the environment. Additionally, its low dust generation contributes to better air quality on job sites, reducing health risks associated with airborne contaminants.

Choosing the Right Garnet Blasting Media for Your Needs

Selecting the appropriate garnet blasting media requires consideration of several factors, including:

1. Application Type

Different applications may require different grades of garnet. For instance, finer grades are ideal for delicate surfaces, while coarser grades are better suited for heavy-duty applications.

2. Surface Material

Consider the material of the surface being blasted. Metal surfaces may require a different garnet grade compared to wood or plastic surfaces.

3. Desired Finish

The desired finish will also influence your choice of garnet grade. Higher grades yield a smoother finish, while lower grades are more aggressive.

4. Equipment Compatibility

Ensure that the garnet you choose is compatible with your blasting equipment to achieve optimal performance.

Frequently Asked Questions

1. What is garnet blasting media made of?

Garnet blasting media is made from crushed garnet stones, which are processed into various grades for different applications.

2. Is garnet blasting media safe to use?

Yes, garnet blasting media is considered safe to use, particularly because it is a natural mineral that does not contain harmful chemicals.

3. How is garnet blasting media different from other abrasives?

Garnet blasting media is harder and has a more angular shape compared to many other abrasives, which enhances its cutting ability and effectiveness.

4. Can garnet be reused?

Yes, garnet blasting media can be reused multiple times, depending on the application and the condition of the particles.

5. Where can I buy garnet blasting media?

Garnet blasting media is available from various suppliers, both online and in physical stores specializing in industrial abrasives.

Conclusion

Garnet blasting media emerges as a **versatile and efficient abrasive solution** across various industries. Its unique properties, ranging from exceptional hardness to eco-friendliness, make it a preferred choice for numerous applications. By understanding its capabilities and benefits, businesses can make informed decisions that enhance productivity while promoting sustainable practices. Choosing garnet blasting media not only elevates the quality of work but also contributes positively to the environment, making it an invaluable asset in modern industrial operations.

News

Exploring the Versatility of Garnet Blasting Media in Various Industries

Exploring the Versatility of Garnet Blasting Media in Various Industries Table of Contents Introduction to Garnet Blasting Media What is Garnet Blasting Media? Key Properties of Garnet Blasting Media Applications of Garnet Blasting Media in Various Industries Garnet in the Construction Industry Garnet in the Automotive Industry Garnet i

The Ultimate Guide to Choosing Aluminum Oxide Blast Media for Your Projects

The Ultimate Guide to Choosing Aluminum Oxide Blast Media for Your Projects Table of Contents 1. Introduction to Aluminum Oxide Blast Media 2. What is Aluminum Oxide? 3. Benefits of Using Aluminum Oxide Blast Media 4. Types of Aluminum Oxide Blast Media 4.1 Crushed Aluminum Oxide 4.2 Fused Aluminum Oxide 5. How to Choose the Right Grad

The Ultimate Guide to Steel Shot Abrasive Blasting Techniques: Achieving Optimal Surface Finishing

The Ultimate Guide to Steel Shot Abrasive Blasting Techniques Steel shot abrasive blasting is an essential process widely used in various industries for surface preparation, cleaning, and finishing. Its effectiveness in removing contaminants and preparing surfaces makes it a preferred choice for many applications. This guide aims to explore the intricacies of steel shot abrasive blasting technique

How to Choose the Right Cut Wire Shot for Your Project

How to Choose the Right Cut Wire Shot for Your Project Table of Contents Introduction to Cut Wire Shot What is Cut Wire Shot? Types of Cut Wire Shot Steel Cut Wire Shot Copper Cut Wire Shot Stainless Steel Cut Wire Shot How to Choose the Right Cut Wire Shot Key Considerations for Selection Understanding

The Impact of Shot Blasting on Surface Finishing Quality: A Comprehensive Guide

The Impact of Shot Blasting on Surface Finishing Quality Table of Contents 1. Introduction to Shot Blasting 2. Understanding Surface Finishing Quality 3. How Shot Blasting Works 4. Benefits of Shot Blasting in Surface Finishing 5. Applications of Shot Blasting Across Industries 6. Best Practices for Shot Blasting 7. Common Misconceptions About Shot Blasting 8. The

Exploring the Efficiency of Steel Cut Wire Shot in Industrial Applications

Exploring the Efficiency of Steel Cut Wire Shot in Industrial Applications Table of Contents Introduction to Steel Cut Wire Shot Benefits of Using Steel Cut Wire Shot Applications of Steel Cut Wire Shot in Industry Efficiency Factors in Steel Cut Wire Shot Composition and Manufacturing Process Selecting the Right Steel Cut Wire Shot Environmental Impact and Sustainabil