The Ultimate Guide to Steel Shot Abrasive Blasting Techniques: Achieving Optimal Surface Finishing

Release time:

2025-07-05

The Ultimate Guide to Steel Shot Abrasive Blasting Techniques Steel shot abrasive blasting is an essential process widely used in various industries for surface preparation, cleaning, and finishing. Its effectiveness in removing contaminants and preparing surfaces makes it a preferred choice for many applications. This guide aims to explore the intricacies of steel shot abrasive blasting technique

The Ultimate Guide to Steel Shot Abrasive Blasting Techniques

Steel shot abrasive blasting is an essential process widely used in various industries for surface preparation, cleaning, and finishing. Its effectiveness in removing contaminants and preparing surfaces makes it a preferred choice for many applications. This guide aims to explore the intricacies of steel shot abrasive blasting techniques, offering valuable insights into their applications, advantages, and best practices.

Table of Contents

- 1. Introduction to Steel Shot Abrasive Blasting

- 2. What is Steel Shot?

- 3. Applications of Steel Shot Abrasive Blasting

- 4. Advantages of Using Steel Shot

- 5. Steel Shot Blasting Techniques

- 6. Equipment Used in Steel Shot Blasting

- 7. Best Practices for Effective Blasting

- 8. Safety Considerations in Steel Shot Blasting

- 9. Frequently Asked Questions

- 10. Conclusion

1. Introduction to Steel Shot Abrasive Blasting

Steel shot abrasive blasting is a method that utilizes small steel pellets to clean, prepare, or finish a surface. The process involves propelling these pellets at high velocities onto the surface, causing the surface material or contaminants to be removed or smoothed out. This technique is particularly valued in industries such as automotive, aerospace, and metal fabrication, where precision and surface quality are paramount.

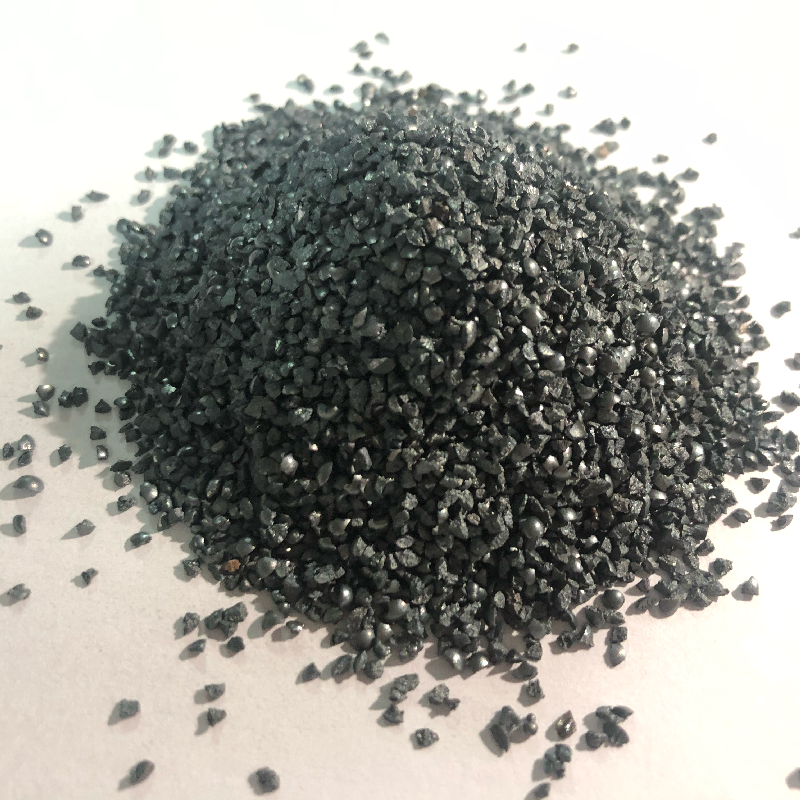

2. What is Steel Shot?

Steel shot refers to small, spherical pellets made of steel that are used as abrasive media in blasting applications. These pellets come in various sizes and hardness levels, allowing them to be tailored to specific applications. The spherical shape of steel shot provides a unique advantage in that it delivers a uniform and consistent finish, making it an ideal choice for surface preparation and cleaning.

2.1 Types of Steel Shot

There are different types of steel shot, classified based on their production method and hardness:

- Cast Steel Shot: Produced by casting molten steel into spherical shapes, this type is commonly used for general blasting applications.

- Wrought Steel Shot: This type is manufactured by forging and rolling steel, offering higher durability and uniformity.

- Stainless Steel Shot: Used for applications where corrosion resistance is required, stainless steel shot provides a clean finish while maintaining material integrity.

3. Applications of Steel Shot Abrasive Blasting

Steel shot abrasive blasting has a diverse range of applications across various industries. Some of the most common include:

3.1 Surface Preparation

Before applying coatings or paint, it is essential to prepare the surface adequately. Steel shot blasting effectively removes rust, old paint, and contaminants, ensuring a smooth foundation for further treatment.

3.2 Cleaning Metal Components

In manufacturing processes, steel shot blasting is used to clean metal components, removing oils, dirt, and other debris that can affect performance and aesthetics.

3.3 Surface Finishing

Steel shot blasting imparts a uniform finish on components, enhancing their visual appeal and functionality. This is particularly important in industries where the appearance of products is crucial.

4. Advantages of Using Steel Shot

Choosing steel shot for abrasive blasting comes with numerous advantages:

4.1 Enhanced Surface Quality

The spherical nature of steel shot generates a consistent and smooth finish, which is critical for applications requiring high-quality surface standards.

4.2 Cost-Effectiveness

Steel shot is durable and can be reused multiple times before being replaced, offering significant savings in material costs over time.

4.3 Environmental Considerations

Using steel shot reduces the amount of waste produced compared to other abrasive materials, making it a more environmentally friendly choice.

5. Steel Shot Blasting Techniques

Understanding the different techniques of steel shot blasting is crucial for achieving optimal results.

5.1 Airless Blasting

Airless blasting utilizes compressed air to propel steel shot at high velocities. This technique is ideal for large surface areas and provides an efficient method of blasting.

5.2 Blast Cabinet Techniques

Using a blast cabinet allows for precise control over the blasting process. This technique is often used for smaller parts and offers a contained environment for efficient operation.

5.3 Wheel Blasting

Wheel blasting employs a rotating wheel to accelerate the steel shot, providing a high-impact blasting technique suitable for larger components and heavy-duty applications.

6. Equipment Used in Steel Shot Blasting

The effectiveness of steel shot abrasive blasting heavily depends on the equipment used. Key equipment includes:

6.1 Blast Machines

These machines control the flow of steel shot and the air pressure, ensuring a consistent blasting process.

6.2 Blast Cabinets

Blast cabinets provide a controlled environment for blasting smaller components, reducing waste and enhancing safety.

6.3 Dust Collectors

To maintain a clean working environment, dust collectors are employed to capture airborne particles generated during the blasting process.

7. Best Practices for Effective Blasting

To achieve the best results with steel shot abrasive blasting, follow these best practices:

7.1 Selecting the Correct Shot Size

Choosing the right size of steel shot is vital for obtaining the desired finish and ensuring efficient material removal.

7.2 Regular Equipment Maintenance

Maintaining blasting equipment is crucial for consistent performance and longevity. Regular inspections and servicing should be conducted.

7.3 Proper Blasting Techniques

Employing the correct blasting angle and distance enhances efficiency and ensures a uniform finish across the surface.

8. Safety Considerations in Steel Shot Blasting

Safety is paramount in any abrasive blasting operation. Key safety measures include:

8.1 Personal Protective Equipment (PPE)

Workers should always wear appropriate PPE, including helmets, goggles, gloves, and respirators to protect against flying particles and dust inhalation.

8.2 Ventilation

Ensuring proper ventilation in the blasting area minimizes the risk of exposure to harmful dust and improves overall air quality.

8.3 Training

All personnel should be adequately trained in safe blasting practices and emergency procedures to minimize potential risks.

9. Frequently Asked Questions

9.1 What is the difference between steel shot and steel grit?

Steel shot is spherical and used for achieving smooth finishes, while steel grit is angular and better suited for aggressive material removal.

9.2 How often should steel shot be replaced?

The lifespan of steel shot depends on usage. Generally, it can be reused until it breaks down to a certain size or loses its effectiveness.

9.3 Can steel shot be used on all materials?

While steel shot is effective on many metals, it may not be suitable for softer materials like aluminum or certain plastics.

9.4 Is steel shot blasting environmentally friendly?

Yes, steel shot is a more sustainable option compared to many other abrasive materials, as it produces less waste and can be recycled.

9.5 What safety measures are necessary during steel shot blasting?

Proper PPE, good ventilation, and training for operators are critical safety measures to mitigate risks during the blasting process.

10. Conclusion

Steel shot abrasive blasting is an invaluable technique for achieving superior surface quality and preparing materials for further treatment. By understanding the various techniques, applications, and best practices, industries can leverage this method to enhance productivity and ensure consistent results. Implementing safety measures and utilizing the right equipment will further enable businesses to achieve optimal outcomes in their abrasive blasting operations. Embracing steel shot abrasive blasting will undoubtedly lead to improved efficiency and effectiveness in surface preparation across diverse industries.

News

The Ultimate Guide to Steel Shot Abrasive Blasting Techniques: Achieving Optimal Surface Finishing

The Ultimate Guide to Steel Shot Abrasive Blasting Techniques Steel shot abrasive blasting is an essential process widely used in various industries for surface preparation, cleaning, and finishing. Its effectiveness in removing contaminants and preparing surfaces makes it a preferred choice for many applications. This guide aims to explore the intricacies of steel shot abrasive blasting technique

How to Choose the Right Cut Wire Shot for Your Project

How to Choose the Right Cut Wire Shot for Your Project Table of Contents Introduction to Cut Wire Shot What is Cut Wire Shot? Types of Cut Wire Shot Steel Cut Wire Shot Copper Cut Wire Shot Stainless Steel Cut Wire Shot How to Choose the Right Cut Wire Shot Key Considerations for Selection Understanding

The Impact of Shot Blasting on Surface Finishing Quality: A Comprehensive Guide

The Impact of Shot Blasting on Surface Finishing Quality Table of Contents 1. Introduction to Shot Blasting 2. Understanding Surface Finishing Quality 3. How Shot Blasting Works 4. Benefits of Shot Blasting in Surface Finishing 5. Applications of Shot Blasting Across Industries 6. Best Practices for Shot Blasting 7. Common Misconceptions About Shot Blasting 8. The

Exploring the Efficiency of Steel Cut Wire Shot in Industrial Applications

Exploring the Efficiency of Steel Cut Wire Shot in Industrial Applications Table of Contents Introduction to Steel Cut Wire Shot Benefits of Using Steel Cut Wire Shot Applications of Steel Cut Wire Shot in Industry Efficiency Factors in Steel Cut Wire Shot Composition and Manufacturing Process Selecting the Right Steel Cut Wire Shot Environmental Impact and Sustainabil

The Benefits and Applications of Shot Blasting with Steel Shot

Shot blasting with steel shot is a crucial process in various industrial applications, especially in the metalworking and manufacturing sectors. This method involves propelling small steel balls at high velocities onto a surface to remove contaminants, prepare surfaces for further treatment, and improve the overall quality of the material. Understanding the benefits and applications of shot blasti

The Science Behind Stainless Steel Shot Abrasion Techniques: A Comprehensive Guide

The Science Behind Stainless Steel Shot Abrasion Techniques Table of Contents 1. Introduction to Stainless Steel Shot Abrasion 2. Understanding the Basics of Abrasive Techniques 3. The Role of Stainless Steel Shots in Abrasion 3.1 Definition and Composition of Stainless Steel Shots 3.2 Types of Stainless Steel Shots 4. Mechanism of Stainless Steel Shot Abrasion 4.1 Process Overview 4.2 Key Paramet