How Stainless Steel Grit Blasting Media Enhances the Durability of Metal Surfaces

Release time:

2025-07-26

How Stainless Steel Grit Blasting Media Enhances the Durability of Metal Surfaces In today's competitive industrial landscape, ensuring the longevity and durability of metal surfaces is crucial. One of the most effective methods for achieving this is through **stainless steel grit blasting**. This article explores how this technique not only enhances the durability of metal surfaces but also optim

How Stainless Steel Grit Blasting Media Enhances the Durability of Metal Surfaces

In today's competitive industrial landscape, ensuring the longevity and durability of metal surfaces is crucial. One of the most effective methods for achieving this is through **stainless steel grit blasting**. This article explores how this technique not only enhances the durability of metal surfaces but also optimizes performance, appearance, and resistance to corrosion. By understanding the nuances of grit blasting, industries can significantly improve their metal products.

Table of Contents

- What is Grit Blasting?

- The Science of Stainless Steel Grit

- Benefits of Using Stainless Steel Grit Blasting Media

- Enhancing Durability Through Grit Blasting

- Applications of Stainless Steel Grit Blasting

- Choosing the Right Grit Blasting Media

- Safety Measures in Grit Blasting

- Frequently Asked Questions

- Conclusion

What is Grit Blasting?

Grit blasting, also known as abrasive blasting or sandblasting, is a process that involves propelling abrasive materials against a surface under high pressure. This method serves multiple purposes, including surface cleaning, shaping, and the preparation of metal surfaces for further processing or coating. The use of **stainless steel grit** specifically offers unique advantages due to its hardness, durability, and non-reactive properties.

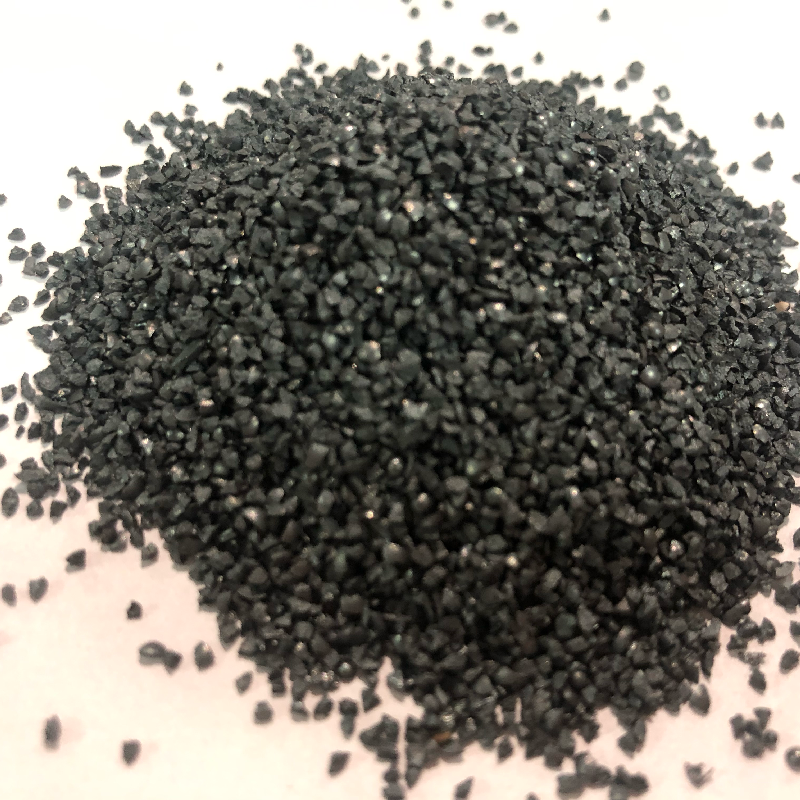

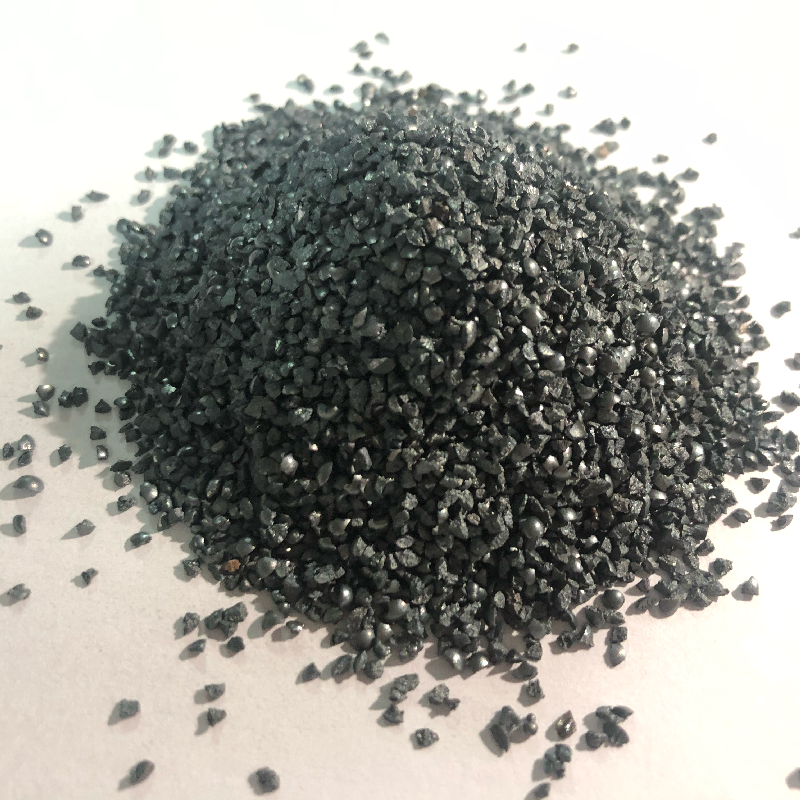

The Science of Stainless Steel Grit

Stainless steel grit is made from high-quality stainless steel, which gives it exceptional hardness and resistance to wear and tear. Unlike traditional abrasives such as sand or aluminum oxide, stainless steel grit is less likely to break down during use, leading to a more consistent finish. The particle size can vary, allowing for customized applications depending on the surface finish required. This grit also minimizes contamination risks since it does not rust or corrode, making it ideal for industries that prioritize cleanliness and safety.

Benefits of Using Stainless Steel Grit Blasting Media

1. Enhanced Surface Finish

One of the primary benefits of using stainless steel grit is the superior surface finish it provides. The grit can achieve a finely textured surface that improves adhesion for subsequent coatings or treatments. This results in a more aesthetically pleasing appearance and improved performance characteristics.

2. Corrosion Resistance

Stainless steel grit significantly enhances the corrosion resistance of metal surfaces. By creating a rough texture, it allows protective coatings to bond better, reducing the likelihood of rust and degradation over time. This is particularly beneficial for metals exposed to harsh environmental conditions.

3. Increased Fatigue Strength

The peening effect created by grit blasting can enhance the fatigue strength of metal surfaces. This occurs as the process induces compressive stresses on the surface, leading to improved resistance to cracking and failure under cyclic loads.

4. Eco-Friendliness

Using stainless steel grit is more environmentally friendly than many traditional abrasive materials. Since it does not produce harmful dust or residues, the overall environmental impact is minimized. Additionally, the grit can be recycled multiple times, making it a sustainable choice for industries.

5. Versatility

Stainless steel grit can be used across various industries and applications, from automotive and aerospace to construction and restoration. Its versatility makes it a go-to choice for businesses looking to enhance metal durability across multiple sectors.

Enhancing Durability Through Grit Blasting

Durability is a key factor in the performance of metal products. Stainless steel grit blasting enhances durability by addressing common issues such as surface defects, corrosion, and wear. The process effectively removes oxidation, paint, and other contaminants, providing a clean surface for further treatments. This preparation not only extends the life of the metal but also ensures optimal functionality in its intended application.

Improved Adhesion for Coatings

For metals that undergo coatings or painting, effective surface preparation is critical. Stainless steel grit blasting creates micro-abrasions that improve the bonding surface for paints and coatings, resulting in a stronger and more durable finish. This is especially important in industries where machinery and structural components are exposed to extreme conditions.

Minimized Wear and Tear

The enhanced surface texture achieved through grit blasting reduces wear and tear on metal parts. For components that experience friction, such as gears and bearings, this minimized wear translates to longer service life and reduced maintenance costs, benefiting businesses both operationally and financially.

Applications of Stainless Steel Grit Blasting

Stainless steel grit blasting finds applications in a variety of industries due to its effectiveness and versatility. Some key applications include:

1. Automotive Industry

In the automotive sector, stainless steel grit blasting is utilized for cleaning engine parts, preparing surfaces for painting, and improving the corrosion resistance of various components.

2. Aerospace Manufacturing

The aerospace industry demands high-performance materials. Stainless steel grit blasting is used to achieve precise surface finishes on parts, enhancing durability and performance under extreme conditions.

3. Construction and Infrastructure

In construction, stainless steel grit is applied to prepare metal surfaces for coatings, ensuring long-lasting protection against environmental elements.

4. Metal Restoration

For restoration projects, such as vintage cars or historical buildings, stainless steel grit blasting provides a clean slate by effectively removing old paint and rust, while preserving the integrity of the underlying metal.

Choosing the Right Grit Blasting Media

When selecting the appropriate grit blasting media, several factors should be considered:

1. Material Type

Different metals may require specific media to achieve the desired finish. For instance, softer metals might benefit from finer grits, while harder materials may require coarser options.

2. Desired Finish

Determine the required surface finish for your project. The choice of grit size and type will significantly impact the end result, so selecting the appropriate media is crucial for achieving the desired outcome.

3. Environmental Regulations

Be aware of environmental regulations regarding abrasive materials. Stainless steel grit is generally more compliant due to its reduced environmental impact, but it's important to confirm compliance with local regulations.

Safety Measures in Grit Blasting

Ensuring safety during grit blasting operations is paramount. Here are essential safety measures to consider:

1. Personal Protective Equipment (PPE)

Always wear appropriate PPE, including respirators, goggles, gloves, and protective clothing, to safeguard against harmful dust and flying debris.

2. Proper Equipment Maintenance

Regularly maintain blasting equipment to prevent malfunctions and ensure optimal performance. Routine checks and servicing can enhance both safety and efficiency.

3. Work Area Containment

Set up containment measures to control dust and debris. This can include using blast curtains or enclosures to protect the surrounding environment and workers.

Frequently Asked Questions

1. What materials can be treated with stainless steel grit blasting?

Stainless steel grit blasting can be used on a wide variety of metals, including aluminum, steel, and titanium, making it suitable for numerous applications across various industries.

2. How does stainless steel grit compare to other blasting media?

Stainless steel grit is more durable and less prone to breakdown than traditional abrasives. It also provides a cleaner finish and reduces the risk of contamination, making it a superior choice for many applications.

3. Is grit blasting environmentally friendly?

Yes, stainless steel grit is environmentally friendly as it produces less dust and can be recycled multiple times, minimizing waste and environmental impact.

4. Can grit blasting improve the lifespan of metal components?

Absolutely! Grit blasting enhances the durability and fatigue strength of metal surfaces, significantly extending the lifespan of components exposed to wear and environmental conditions.

5. What safety equipment is necessary when performing grit blasting?

Essential PPE includes respirators, goggles, gloves, and protective clothing. Ensuring a safe working environment is critical to protect workers from hazards associated with grit blasting.

Conclusion

Stainless steel grit blasting is a game-changer in the realm of metal surface preparation and durability enhancement. It offers unparalleled benefits, including improved surface finish, enhanced corrosion resistance, and increased fatigue strength. By understanding the intricacies of this method and selecting the right grit for specific applications, industries can not only enhance the performance of metal surfaces but also extend their lifespan. As we continue to innovate and seek sustainable solutions, stainless steel grit will undoubtedly play a vital role in shaping the future of metal manufacturing and maintenance.

News

How Stainless Steel Grit Blasting Media Enhances the Durability of Metal Surfaces

How Stainless Steel Grit Blasting Media Enhances the Durability of Metal Surfaces In today's competitive industrial landscape, ensuring the longevity and durability of metal surfaces is crucial. One of the most effective methods for achieving this is through **stainless steel grit blasting**. This article explores how this technique not only enhances the durability of metal surfaces but also optim

Exploring the Versatility of Garnet Blasting Media in Various Industries

Exploring the Versatility of Garnet Blasting Media in Various Industries Table of Contents Introduction to Garnet Blasting Media What is Garnet Blasting Media? Key Properties of Garnet Blasting Media Applications of Garnet Blasting Media in Various Industries Garnet in the Construction Industry Garnet in the Automotive Industry Garnet i

The Ultimate Guide to Choosing Aluminum Oxide Blast Media for Your Projects

The Ultimate Guide to Choosing Aluminum Oxide Blast Media for Your Projects Table of Contents 1. Introduction to Aluminum Oxide Blast Media 2. What is Aluminum Oxide? 3. Benefits of Using Aluminum Oxide Blast Media 4. Types of Aluminum Oxide Blast Media 4.1 Crushed Aluminum Oxide 4.2 Fused Aluminum Oxide 5. How to Choose the Right Grad

The Ultimate Guide to Steel Shot Abrasive Blasting Techniques: Achieving Optimal Surface Finishing

The Ultimate Guide to Steel Shot Abrasive Blasting Techniques Steel shot abrasive blasting is an essential process widely used in various industries for surface preparation, cleaning, and finishing. Its effectiveness in removing contaminants and preparing surfaces makes it a preferred choice for many applications. This guide aims to explore the intricacies of steel shot abrasive blasting technique

How to Choose the Right Cut Wire Shot for Your Project

How to Choose the Right Cut Wire Shot for Your Project Table of Contents Introduction to Cut Wire Shot What is Cut Wire Shot? Types of Cut Wire Shot Steel Cut Wire Shot Copper Cut Wire Shot Stainless Steel Cut Wire Shot How to Choose the Right Cut Wire Shot Key Considerations for Selection Understanding

The Impact of Shot Blasting on Surface Finishing Quality: A Comprehensive Guide

The Impact of Shot Blasting on Surface Finishing Quality Table of Contents 1. Introduction to Shot Blasting 2. Understanding Surface Finishing Quality 3. How Shot Blasting Works 4. Benefits of Shot Blasting in Surface Finishing 5. Applications of Shot Blasting Across Industries 6. Best Practices for Shot Blasting 7. Common Misconceptions About Shot Blasting 8. The