Unlocking Efficiency: The Benefits of Using a Blast Track Shot Blaster in Metalworking

Release time:

2025-08-02

Unlocking Efficiency: The Benefits of Using a Blast Track Shot Blaster in Metalworking Table of Contents Introduction to Blast Track Shot Blasters What is a Blast Track Shot Blaster? Key Benefits of Using a Blast Track Shot Blaster Enhanced Surface Preparation Time Efficiency and Productivity Cost-Effectiveness in Operations Versatility Across Various Applicatio

Unlocking Efficiency: The Benefits of Using a Blast Track Shot Blaster in Metalworking

Table of Contents

- Introduction to Blast Track Shot Blasters

- What is a Blast Track Shot Blaster?

- Key Benefits of Using a Blast Track Shot Blaster

- Enhanced Surface Preparation

- Time Efficiency and Productivity

- Cost-Effectiveness in Operations

- Versatility Across Various Applications

- How a Blast Track Shot Blaster Works

- Maintenance Tips for Optimal Performance

- Environmental Considerations

- Frequently Asked Questions

- Conclusion

Introduction to Blast Track Shot Blasters

In the ever-evolving landscape of metalworking, efficient surface preparation stands out as a critical factor in ensuring quality and durability. A **Blast Track Shot Blaster** has emerged as an invaluable tool, enhancing the overall productivity and effectiveness of metalworking operations. In this article, we will delve into the numerous benefits of using a Blast Track Shot Blaster, exploring how it can transform your metalworking processes.

What is a Blast Track Shot Blaster?

A **Blast Track Shot Blaster** is an advanced piece of equipment used to clean, prepare, and finish metal surfaces. This powerful tool utilizes high-velocity steel shot or abrasive materials to remove rust, scales, and contaminants from metal surfaces. The blasting process not only prepares the surface for further treatments, such as painting or coating, but also enhances the overall appearance and longevity of the materials.

Key Benefits of Using a Blast Track Shot Blaster

Enhanced Surface Preparation

One of the most significant advantages of using a Blast Track Shot Blaster is its ability to provide **superior surface preparation**. The high-speed impact of the abrasive materials effectively removes contaminants, ensuring a clean substrate for further processes. Whether you're preparing metals for painting, welding, or coating, a clean surface guarantees better adhesion and reduces the risk of defects.

Time Efficiency and Productivity

In the fast-paced environment of metalworking, time is of the essence. A Blast Track Shot Blaster offers unparalleled efficiency, significantly reducing the time required for surface preparation. Traditional methods, such as manual grinding or chemical stripping, can be labor-intensive and time-consuming. In contrast, the automated nature of a shot blaster allows for rapid processing, enabling operators to focus on other critical tasks, thus boosting overall productivity.

Cost-Effectiveness in Operations

Investing in a Blast Track Shot Blaster can lead to substantial cost savings over time. By streamlining the surface preparation process, companies can reduce labor costs and minimize material waste. Furthermore, enhanced surface preparation reduces the likelihood of premature failure in coatings, leading to longer-lasting finishes and fewer reworks. This cost-effective approach translates to higher profit margins and better resource allocation.

Versatility Across Various Applications

The adaptability of a Blast Track Shot Blaster makes it suitable for a wide range of applications within the metalworking industry. From automotive parts to heavy machinery components, this equipment can be used to prepare various substrates, including ferrous and non-ferrous metals. Its versatility opens new avenues for operations, allowing businesses to expand their service offerings and cater to diverse market needs.

How a Blast Track Shot Blaster Works

Understanding the mechanics behind a Blast Track Shot Blaster can enhance your appreciation for its effectiveness. The machine operates by propelling abrasive materials at high speeds against the surface of the metal. This process creates a mechanical scouring effect, effectively removing contaminants and preparing the surface.

The equipment typically consists of the following components:

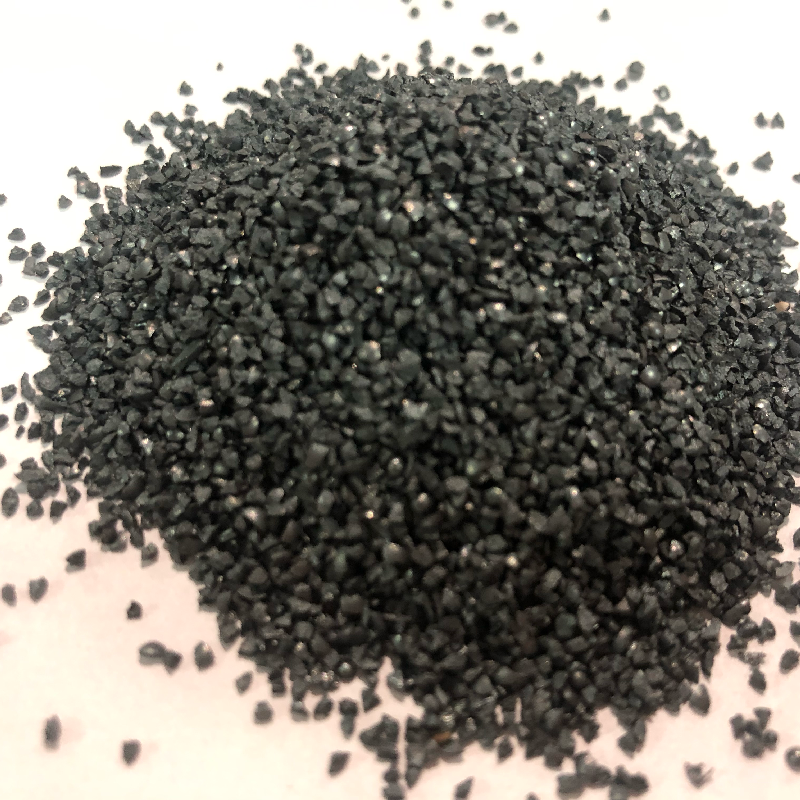

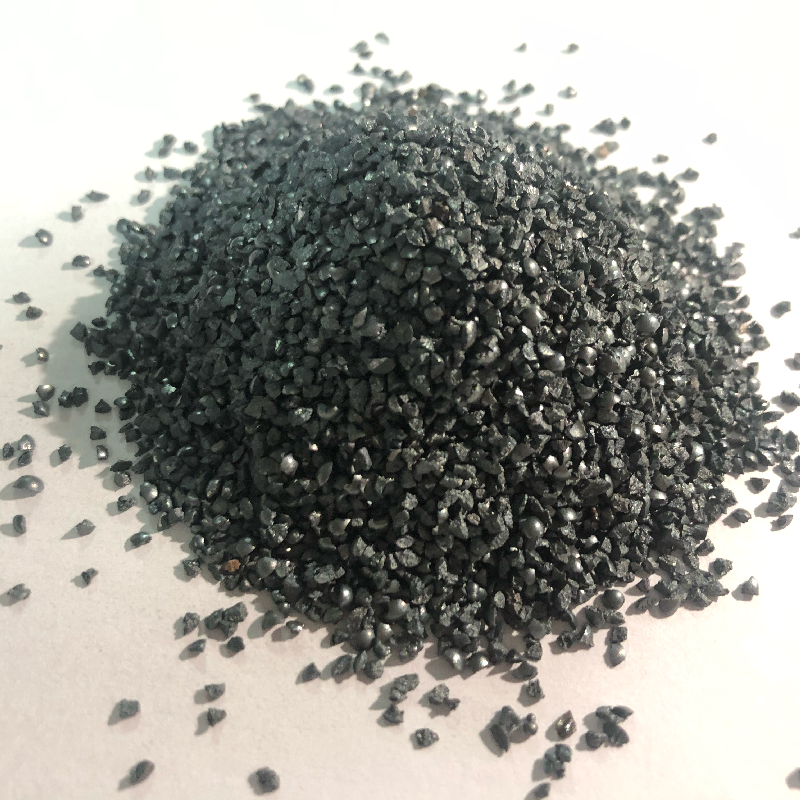

- **Abrasive Hopper**: Stores the blasting media, such as steel shot or abrasive granules.

- **Blasting Wheel**: Spins at high speeds to launch the abrasive materials towards the workpiece.

- **Conveyor System**: Moves the metal pieces through the blasting chamber, ensuring uniform exposure to the blasting media.

- **Dust Collection System**: Captures airborne particles, promoting a cleaner workplace and enhancing safety.

Maintenance Tips for Optimal Performance

To ensure the longevity and efficiency of your Blast Track Shot Blaster, regular maintenance is essential. Here are some key maintenance tips to keep in mind:

1. **Regular Inspections**: Conduct routine checks on all components to identify wear and tear early.

2. **Clean the System**: Regularly clean the hopper and dust collection system to prevent clogs and ensure proper functioning.

3. **Monitor Abrasive Quality**: Use high-quality abrasives and replace them as needed to maintain optimal performance.

4. **Lubrication**: Keep moving parts well-lubricated to reduce friction and wear.

5. **Training**: Ensure that operators are trained in proper usage and maintenance practices to maximize the machine's lifespan.

Environmental Considerations

As industries become more environmentally conscious, the use of a Blast Track Shot Blaster can align with sustainable practices. The machine’s ability to recycle and reuse abrasive materials minimizes waste and reduces the environmental footprint. Additionally, dust collection systems improve air quality, promoting a healthier workplace. By incorporating eco-friendly practices into your operations, you enhance your brand's reputation and contribute to a sustainable future.

Frequently Asked Questions

1. What materials can be used in a Blast Track Shot Blaster?

A Blast Track Shot Blaster can utilize various abrasive materials, including steel shot, garnet, glass beads, and aluminum oxide. The choice of media depends on the specific application and desired finish.

2. How do I choose the right size of Blast Track Shot Blaster for my needs?

Selecting the appropriate size depends on the volume of work and the dimensions of the materials being processed. Assess your production requirements and consult with manufacturers to find the best fit.

3. What safety precautions should I take when using a Blast Track Shot Blaster?

Always wear appropriate PPE, including eye protection, gloves, and respirators. Ensure the blasting area is well-ventilated and follow all manufacturer guidelines for safe operation.

4. Can a Blast Track Shot Blaster be used for both ferrous and non-ferrous metals?

Yes, Blast Track Shot Blasters are versatile and can effectively clean and prepare both ferrous and non-ferrous metals, making them suitable for a wide range of applications.

5. How often should I perform maintenance on my Blast Track Shot Blaster?

Routine maintenance should be conducted regularly, with thorough inspections and cleaning performed at least every few months. The frequency may vary based on usage and operational demands.

Conclusion

In conclusion, the integration of a **Blast Track Shot Blaster** into metalworking processes brings a multitude of benefits, including enhanced surface preparation, increased productivity, cost savings, and versatility across various applications. By effectively streamlining operations and promoting sustainable practices, this powerful tool can significantly elevate the quality and efficiency of metalworking tasks. Investing in a Blast Track Shot Blaster is not just a choice; it’s a strategic decision that can propel your business forward in a competitive market.

Previous

News

Unlocking Efficiency: The Benefits of Using a Blast Track Shot Blaster in Metalworking

Unlocking Efficiency: The Benefits of Using a Blast Track Shot Blaster in Metalworking Table of Contents Introduction to Blast Track Shot Blasters What is a Blast Track Shot Blaster? Key Benefits of Using a Blast Track Shot Blaster Enhanced Surface Preparation Time Efficiency and Productivity Cost-Effectiveness in Operations Versatility Across Various Applicatio

How Stainless Steel Grit Blasting Media Enhances the Durability of Metal Surfaces

How Stainless Steel Grit Blasting Media Enhances the Durability of Metal Surfaces In today's competitive industrial landscape, ensuring the longevity and durability of metal surfaces is crucial. One of the most effective methods for achieving this is through **stainless steel grit blasting**. This article explores how this technique not only enhances the durability of metal surfaces but also optim

Exploring the Versatility of Garnet Blasting Media in Various Industries

Exploring the Versatility of Garnet Blasting Media in Various Industries Table of Contents Introduction to Garnet Blasting Media What is Garnet Blasting Media? Key Properties of Garnet Blasting Media Applications of Garnet Blasting Media in Various Industries Garnet in the Construction Industry Garnet in the Automotive Industry Garnet i

The Ultimate Guide to Choosing Aluminum Oxide Blast Media for Your Projects

The Ultimate Guide to Choosing Aluminum Oxide Blast Media for Your Projects Table of Contents 1. Introduction to Aluminum Oxide Blast Media 2. What is Aluminum Oxide? 3. Benefits of Using Aluminum Oxide Blast Media 4. Types of Aluminum Oxide Blast Media 4.1 Crushed Aluminum Oxide 4.2 Fused Aluminum Oxide 5. How to Choose the Right Grad

The Ultimate Guide to Steel Shot Abrasive Blasting Techniques: Achieving Optimal Surface Finishing

The Ultimate Guide to Steel Shot Abrasive Blasting Techniques Steel shot abrasive blasting is an essential process widely used in various industries for surface preparation, cleaning, and finishing. Its effectiveness in removing contaminants and preparing surfaces makes it a preferred choice for many applications. This guide aims to explore the intricacies of steel shot abrasive blasting technique

How to Choose the Right Cut Wire Shot for Your Project

How to Choose the Right Cut Wire Shot for Your Project Table of Contents Introduction to Cut Wire Shot What is Cut Wire Shot? Types of Cut Wire Shot Steel Cut Wire Shot Copper Cut Wire Shot Stainless Steel Cut Wire Shot How to Choose the Right Cut Wire Shot Key Considerations for Selection Understanding