Exploring the Versatility of Wheelabrator Shot Blasters in Various Industries

Release time:

2025-08-09

Exploring the Versatility of Wheelabrator Shot Blasters in Various Industries Table of Contents Introduction to Wheelabrator Shot Blasters How Wheelabrator Shot Blasters Work Applications of Wheelabrator Shot Blasters in Manufacturing Role of Shot Blasters in Construction and Infrastructure The Automotive Industry: Enhancing Performance with Shot Blasters Aerospace Sector: Meeting Str

Exploring the Versatility of Wheelabrator Shot Blasters in Various Industries

Table of Contents

- Introduction to Wheelabrator Shot Blasters

- How Wheelabrator Shot Blasters Work

- Applications of Wheelabrator Shot Blasters in Manufacturing

- Role of Shot Blasters in Construction and Infrastructure

- The Automotive Industry: Enhancing Performance with Shot Blasters

- Aerospace Sector: Meeting Stringent Standards with Shot Blasting

- Marine Applications: Protecting Vessels with Shot Blasting Technology

- Benefits of Using Wheelabrator Shot Blasters

- Maintenance and Crew Training for Optimal Use

- The Future of Shot Blasting Technology

- Conclusion

- Frequently Asked Questions

Introduction to Wheelabrator Shot Blasters

Wheelabrator shot blasters are sophisticated machines designed to clean, strengthen, and finish surfaces through the use of abrasive materials. As part of the broader category of surface preparation tools, these machines have gained significant traction across multiple sectors. Their versatility and efficiency in achieving optimal surface conditions make them a preferred choice for industries striving to enhance the quality and longevity of their products.

How Wheelabrator Shot Blasters Work

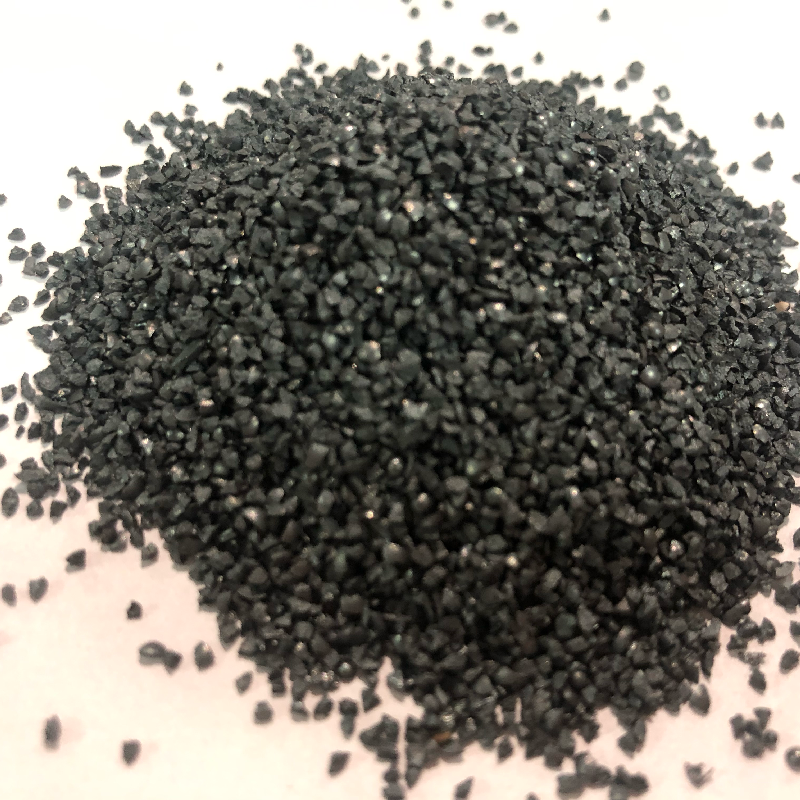

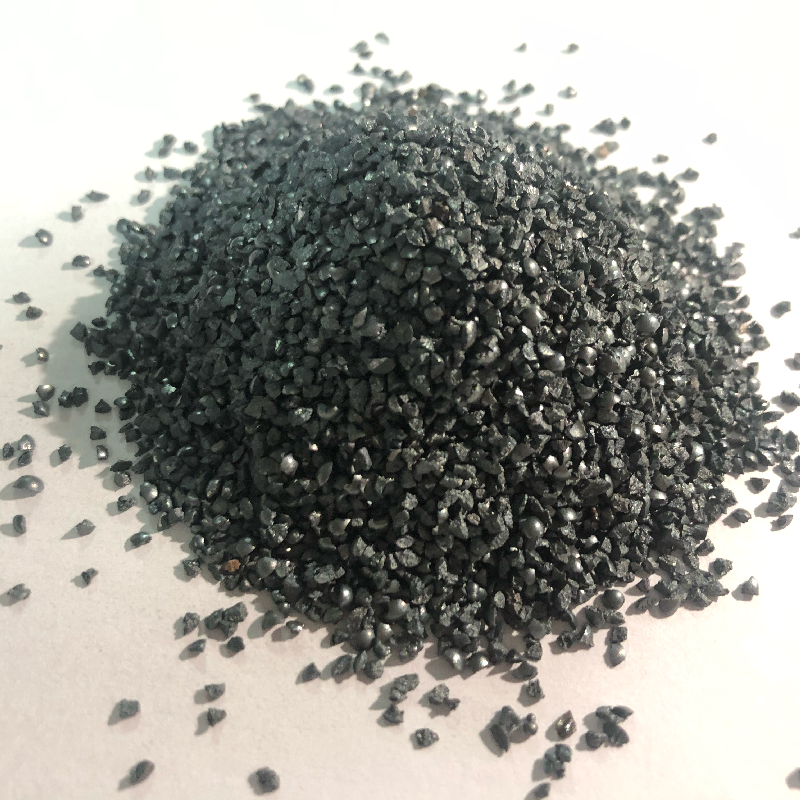

Wheelabrator shot blasters operate by propelling small metal shots or abrasive materials at high velocities onto the surface of components. This process, known as shot blasting, effectively removes contaminants such as rust, scale, and old paint, while also imparting a desired surface finish. The technology behind Wheelabrator machines allows for precise control over the blasting process, ensuring consistent results that meet high-quality standards.

The Mechanism Behind Shot Blasting

The core of a Wheelabrator shot blaster consists of a blast wheel that spins at high speeds, flinging the abrasive media towards the workpiece. The media, which can be made from various materials, can be customized based on the specific requirements of the job. The combination of speed, media type, and angle of impact creates a tailored solution for diverse applications.

Applications of Wheelabrator Shot Blasters in Manufacturing

In the manufacturing sector, Wheelabrator shot blasters play a critical role in surface preparation. They are instrumental in processes such as:

- **Cleaning Metal Parts:** Shot blasters efficiently remove dirt, oil, and other contaminants that could compromise the quality of finished products.

- **Surface Hardening:** The impact of the shots can induce compressive stresses that enhance the fatigue strength of metal components.

- **Preparing Surfaces for Coating:** Properly prepared surfaces improve adhesion for paint and protective coatings, leading to extended product lifespans.

Role of Shot Blasters in Construction and Infrastructure

In the construction industry, Wheelabrator shot blasters are essential for maintaining and restoring concrete surfaces. Their applications include:

- **Concrete Surface Preparation:** Before applying sealants or overlays, shot blasting creates a rough texture that promotes better adhesion.

- **Removing Contaminants from Structures:** Shot blasters effectively eliminate old coatings, contaminants, and surface imperfections from concrete and steel structures.

The Automotive Industry: Enhancing Performance with Shot Blasters

The automotive sector utilizes Wheelabrator shot blasters to ensure components meet stringent performance and safety standards. Key applications include:

- **Cleaning Engine Parts:** High-performance engines require meticulously clean components, which shot blasters provide through their efficient cleaning capabilities.

- **Surface Finishing for Aesthetic Appeal:** The automotive industry often demands high-quality finishes, which can be achieved through targeted shot blasting.

Aerospace Sector: Meeting Stringent Standards with Shot Blasting

The aerospace industry relies on Wheelabrator shot blasters for various critical applications, including:

- **Surface Preparation of Aircraft Components:** Ensuring that materials are free from contaminants and defects is paramount in aerospace manufacturing.

- **Enhancing Material Properties:** Shot blasting can improve the fatigue resistance of components, a critical factor in aerospace engineering.

Marine Applications: Protecting Vessels with Shot Blasting Technology

In the marine sector, Wheelabrator shot blasters are used to protect vessels from corrosion and wear. Their utilization includes:

- **Preparation for Coating Application:** Properly prepared surfaces promote better adhesion of anti-corrosive coatings, extending the lifespan of vessels.

- **Cleaning Hulls:** Regular maintenance of hulls using shot blasters prevents the accumulation of marine growth and fouling.

Benefits of Using Wheelabrator Shot Blasters

The advantages of utilizing Wheelabrator shot blasters extend beyond just surface preparation. Key benefits include:

- **Increased Efficiency:** Shot blasters significantly reduce the time required for cleaning and surface preparation compared to manual methods.

- **Consistent Quality:** Automated processes ensure uniform results, enhancing overall product quality.

- **Cost-Effectiveness:** The durability and efficiency of shot blasters lead to reduced operational costs in the long term.

Maintenance and Crew Training for Optimal Use

To ensure the longevity and effectiveness of Wheelabrator shot blasters, proper maintenance and crew training are essential. Regular inspections and maintenance routines can prevent costly downtimes and repairs. Additionally, training crew members on the intricacies of shot blasting operations ensures that they can maximize the machine's potential while adhering to safety protocols.

The Future of Shot Blasting Technology

As industries evolve, so do the technologies used in shot blasting. The future promises advancements in automation, energy efficiency, and eco-friendly abrasive materials. Continuous research and development will bring forth innovations that enhance performance while minimizing environmental impact.

Conclusion

Wheelabrator shot blasters represent a cornerstone of modern surface preparation across various industries. Their versatility in applications, coupled with the benefits of efficiency, consistent quality, and cost-effectiveness, makes them indispensable tools in manufacturing, construction, aerospace, and marine sectors. By understanding the functionality and potential of these machines, businesses can leverage their capabilities to enhance operational productivity and product quality.

Frequently Asked Questions

1. What types of materials can be used in Wheelabrator shot blasters?

A variety of materials can be used, including steel shots, grit, and other abrasives tailored to specific applications.

2. How often should Wheelabrator shot blasters be maintained?

Regular maintenance schedules are recommended, ideally aligning with the operational hours of the machine to ensure optimal performance.

3. Can Wheelabrator shot blasters be used for both cleaning and finishing?

Yes, they are effective for both cleaning surfaces and achieving desired finishes, depending on the abrasive media and settings used.

4. What safety measures should be taken when using shot blasters?

Operators should wear appropriate personal protective equipment (PPE) and be trained on the machine's operation and safety protocols.

5. Are there eco-friendly options available for shot blasting materials?

Yes, there is an increasing range of eco-friendly abrasives designed to minimize environmental impact while maintaining performance.

By understanding the extensive capabilities of Wheelabrator shot blasters, industries can not only maintain high standards of quality but also adapt to the evolving landscape of manufacturing and surface treatment.

Previous

News

Exploring the Versatility of Wheelabrator Shot Blasters in Various Industries

Exploring the Versatility of Wheelabrator Shot Blasters in Various Industries Table of Contents Introduction to Wheelabrator Shot Blasters How Wheelabrator Shot Blasters Work Applications of Wheelabrator Shot Blasters in Manufacturing Role of Shot Blasters in Construction and Infrastructure The Automotive Industry: Enhancing Performance with Shot Blasters Aerospace Sector: Meeting Str

Unlocking Efficiency: The Benefits of Using a Blast Track Shot Blaster in Metalworking

Unlocking Efficiency: The Benefits of Using a Blast Track Shot Blaster in Metalworking Table of Contents Introduction to Blast Track Shot Blasters What is a Blast Track Shot Blaster? Key Benefits of Using a Blast Track Shot Blaster Enhanced Surface Preparation Time Efficiency and Productivity Cost-Effectiveness in Operations Versatility Across Various Applicatio

How Stainless Steel Grit Blasting Media Enhances the Durability of Metal Surfaces

How Stainless Steel Grit Blasting Media Enhances the Durability of Metal Surfaces In today's competitive industrial landscape, ensuring the longevity and durability of metal surfaces is crucial. One of the most effective methods for achieving this is through **stainless steel grit blasting**. This article explores how this technique not only enhances the durability of metal surfaces but also optim

Exploring the Versatility of Garnet Blasting Media in Various Industries

Exploring the Versatility of Garnet Blasting Media in Various Industries Table of Contents Introduction to Garnet Blasting Media What is Garnet Blasting Media? Key Properties of Garnet Blasting Media Applications of Garnet Blasting Media in Various Industries Garnet in the Construction Industry Garnet in the Automotive Industry Garnet i

The Ultimate Guide to Choosing Aluminum Oxide Blast Media for Your Projects

The Ultimate Guide to Choosing Aluminum Oxide Blast Media for Your Projects Table of Contents 1. Introduction to Aluminum Oxide Blast Media 2. What is Aluminum Oxide? 3. Benefits of Using Aluminum Oxide Blast Media 4. Types of Aluminum Oxide Blast Media 4.1 Crushed Aluminum Oxide 4.2 Fused Aluminum Oxide 5. How to Choose the Right Grad

The Ultimate Guide to Steel Shot Abrasive Blasting Techniques: Achieving Optimal Surface Finishing

The Ultimate Guide to Steel Shot Abrasive Blasting Techniques Steel shot abrasive blasting is an essential process widely used in various industries for surface preparation, cleaning, and finishing. Its effectiveness in removing contaminants and preparing surfaces makes it a preferred choice for many applications. This guide aims to explore the intricacies of steel shot abrasive blasting technique