Understanding Shot Blasting: A Comprehensive Guide for Professionals in the Abrasives Industry

Release time:

2025-08-16

Shot blasting is a widely used technique in the abrasives industry, primarily aimed at cleaning, strengthening, or polishing surfaces. This method involves propelling abrasive materials, commonly referred to as "shots," at high velocities towards a targeted surface. The primary goal of shot blasting is to prepare surfaces for further treatment or to enhance their performance, durability, and aesth

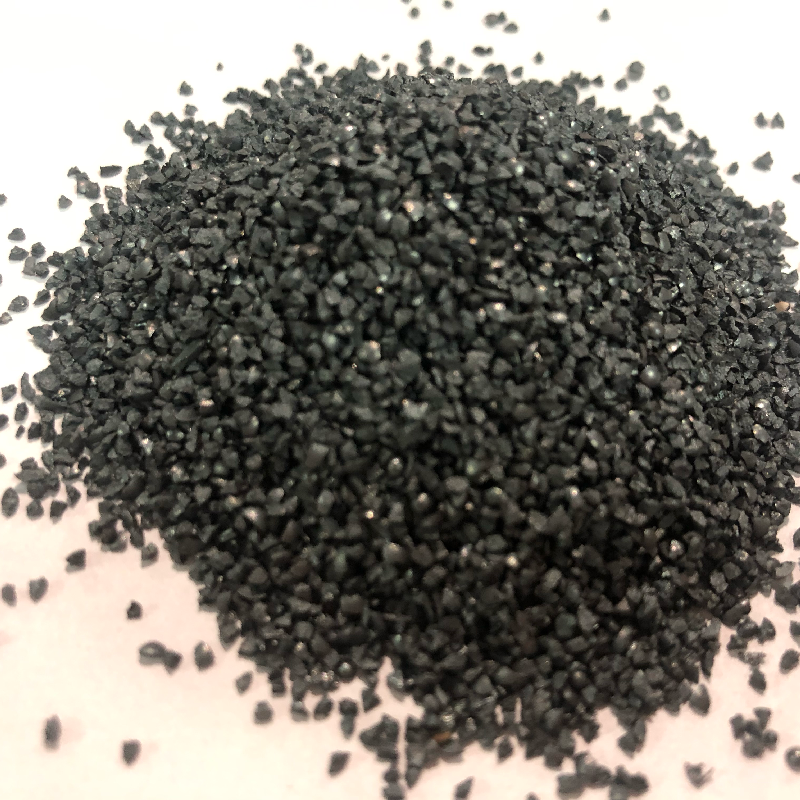

The process begins with the selection of appropriate abrasive materials, which can vary depending on the specific application. Commonly used materials include steel shots, glass beads, aluminum oxide, and various other media. Each type of abrasive has its unique characteristics, influencing factors such as surface finish, cleaning efficiency, and wear resistance. Selecting the right medium is crucial for achieving the desired results without damaging the underlying material.

Shot blasting serves multiple purposes across various industries. In metalworking, for example, it is often employed to remove rust, scale, and other contaminants from metal surfaces prior to painting or coating. This ensures better adhesion of finishes, thereby prolonging the life of the coated surface. In the automotive sector, shot blasting is used to prepare engine components and chassis parts, providing a clean and roughened surface that enhances paint and other surface treatments' adherence.

Beyond cleaning, shot blasting can also be used for surface hardening. By bombarding a surface with high-velocity shots, compressive stresses are induced, which can improve fatigue resistance. This is particularly beneficial for components that undergo cyclic loading, such as gears and springs, where increased durability is essential.

The versatility of shot blasting extends to its applications in various materials, including metals, plastics, and ceramics. For instance, in the construction industry, shot blasting is used to treat concrete surfaces, preparing them for sealing or other finishing processes. This not only enhances the surface's appearance but also improves its resistance to wear and tear.

In terms of operational efficiency, shot blasting systems can be automated, offering consistent quality and reducing labor costs. Advanced technologies, such as robotic shot blasting, have emerged, allowing for precise control over the blasting process. This automation minimizes the risk of human error and enhances productivity, making it an attractive option for manufacturers seeking to optimize their operations.

In conclusion, shot blasting is a vital process in the abrasives industry, offering numerous benefits for surface preparation and treatment. Understanding the various applications and advantages of shot blasting can empower professionals to make informed decisions about their manufacturing processes, ultimately leading to improved product quality and performance.

News

Understanding Shot Blasting: A Comprehensive Guide for Professionals in the Abrasives Industry

Shot blasting is a widely used technique in the abrasives industry, primarily aimed at cleaning, strengthening, or polishing surfaces. This method involves propelling abrasive materials, commonly referred to as "shots," at high velocities towards a targeted surface. The primary goal of shot blasting is to prepare surfaces for further treatment or to enhance their performance, durability, and aesth

Exploring the Versatility of Wheelabrator Shot Blasters in Various Industries

Exploring the Versatility of Wheelabrator Shot Blasters in Various Industries Table of Contents Introduction to Wheelabrator Shot Blasters How Wheelabrator Shot Blasters Work Applications of Wheelabrator Shot Blasters in Manufacturing Role of Shot Blasters in Construction and Infrastructure The Automotive Industry: Enhancing Performance with Shot Blasters Aerospace Sector: Meeting Str

Unlocking Efficiency: The Benefits of Using a Blast Track Shot Blaster in Metalworking

Unlocking Efficiency: The Benefits of Using a Blast Track Shot Blaster in Metalworking Table of Contents Introduction to Blast Track Shot Blasters What is a Blast Track Shot Blaster? Key Benefits of Using a Blast Track Shot Blaster Enhanced Surface Preparation Time Efficiency and Productivity Cost-Effectiveness in Operations Versatility Across Various Applicatio

How Stainless Steel Grit Blasting Media Enhances the Durability of Metal Surfaces

How Stainless Steel Grit Blasting Media Enhances the Durability of Metal Surfaces In today's competitive industrial landscape, ensuring the longevity and durability of metal surfaces is crucial. One of the most effective methods for achieving this is through **stainless steel grit blasting**. This article explores how this technique not only enhances the durability of metal surfaces but also optim

Exploring the Versatility of Garnet Blasting Media in Various Industries

Exploring the Versatility of Garnet Blasting Media in Various Industries Table of Contents Introduction to Garnet Blasting Media What is Garnet Blasting Media? Key Properties of Garnet Blasting Media Applications of Garnet Blasting Media in Various Industries Garnet in the Construction Industry Garnet in the Automotive Industry Garnet i

The Ultimate Guide to Choosing Aluminum Oxide Blast Media for Your Projects

The Ultimate Guide to Choosing Aluminum Oxide Blast Media for Your Projects Table of Contents 1. Introduction to Aluminum Oxide Blast Media 2. What is Aluminum Oxide? 3. Benefits of Using Aluminum Oxide Blast Media 4. Types of Aluminum Oxide Blast Media 4.1 Crushed Aluminum Oxide 4.2 Fused Aluminum Oxide 5. How to Choose the Right Grad